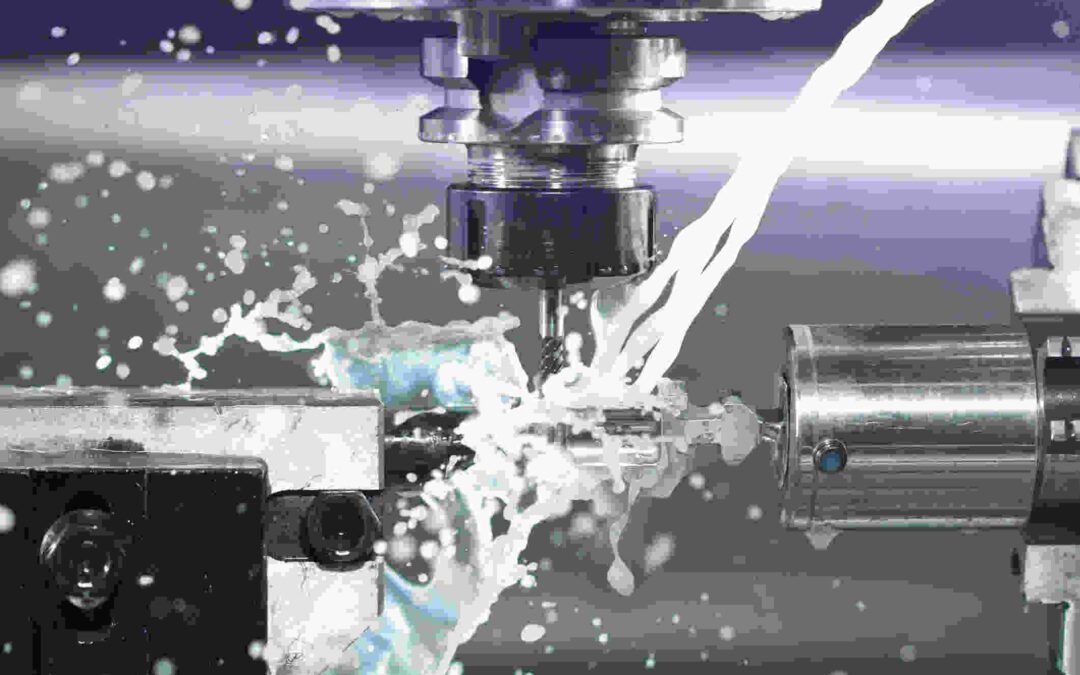

Coolant systems play a critical yet often underappreciated role in determining the precision, reliability, and overall quality of CNC machining processes. As modern manufacturing pushes for tighter tolerances, faster production cycles, and increasingly complex geometries, the demands placed on CNC machines have risen significantly. The resulting heat generated from high-speed cutting, friction between tool and workpiece, and the continuous removal of material can quickly degrade machining accuracy if not managed effectively. Coolant systems address these issues by dissipating heat, lubricating the cutting zone, and carrying away chips that otherwise disrupt tool engagement. The precision of CNC machining relies on maintaining a stable temperature environment, preventing tool wear, and ensuring consistent cutting conditions across long production cycles. Without the evolution of highly efficient coolant delivery solutions, today’s aerospace, medical device, automotive, and semiconductor industries could not achieve the ultra-precise tolerances that modern designs require. As manufacturers adopt smaller tooling, harder materials, and multi-axis operations, coolant systems have become essential components that directly shape productivity and the final dimensional accuracy of every machined part.

One of the most significant ways coolant systems influence precision is through effective thermal control. Heat is an unavoidable byproduct of high-speed machining, especially when cutting dense metals such as stainless steel, titanium, or superalloys. Even slight thermal expansion—fractions of a millimeter—can push a part out of tolerance, especially in precision-critical sectors like aerospace flight components or orthopedic implants. By rapidly removing heat from both the cutting tool and the workpiece, coolant systems prevent thermal distortion and maintain dimensional stability. Flood coolant, mist cooling, through-spindle coolant, and high-pressure coolant all serve unique purposes depending on material properties and machining strategies. High-pressure coolant systems, for example, deliver coolant at pressures exceeding 1,000 psi, penetrating deep into complex tool geometries and flushing chips away instantly. This type of thermal and chip control ensures a consistent cutting temperature, which allows CNC machines to maintain repeatability even across long machining intervals. The reliability of dimensions from the first part to the hundredth is significantly enhanced when temperature remains stable, making advanced coolant systems a vital tool for maintaining tight part specifications in competitive manufacturing environments.

Beyond thermal management, coolant systems play an essential role in tool life extension, which indirectly affects machining precision. Cutting tools endure extreme stress as they slice through various materials, and even minor tool wear can produce dimensional errors, surface imperfections, or inconsistent profiles. Proper lubrication reduces friction between the cutting edge and the workpiece, decreasing wear rates and minimizing the risk of microchipping. Longer tool life means more stable cutting geometry over time, allowing manufacturers to run longer production cycles without unplanned tool changes that can introduce variability. Through-tool coolant delivery is especially valuable for deep-hole drilling or milling operations, where lubrication at the exact cutting point is necessary to prevent premature wear. As carbide, ceramic, and coated tools become more advanced and more expensive, optimizing coolant flow ensures that every tool performs consistently within its intended lifespan. The relationship between coolant and tool wear is direct: a well-cooled, well-lubricated tool produces cleaner cuts, maintains its cutting geometry longer, and delivers parts with tighter tolerances. For manufacturers seeking maximum precision, controlled tool wear enabled by effective coolant strategies is as important as machine rigidity and cutting parameters.

Another major factor influenced by coolant systems is chip evacuation, which plays a surprisingly central role in machining accuracy. When chips accumulate around the cutting zone, they can be recut, creating additional heat, altering the cutting forces, and damaging surface finishes. Recutting chips can also deflect the tool path, leading to micron-level deviations that accumulate over multiple operations. Coolant systems that provide strong flushing capabilities ensure that chips are carried away from the cutting zone immediately, preserving the optimal cutting environment. In multi-axis machining, horizontal milling, or high-speed pocketing, chips can easily become trapped in pockets or cavities, making chip evacuation even more critical. High-pressure and through-spindle coolant systems help prevent chip packing, which otherwise creates unpredictable cutting conditions that compromise precision. Clean cutting zones also allow CNC machines to maintain smoother tool paths, improving surface quality and reducing the need for secondary finishing processes. Thus, chip management is inseparable from precision machining, and the effectiveness of a coolant system’s flushing power directly contributes to the final accuracy and consistency of finished parts.

Advanced coolant technologies have also reshaped CNC machining by enabling new operational strategies that enhance precision. Minimum quantity lubrication (MQL), for example, replaces traditional flood coolant in certain applications by applying extremely fine oil droplets directly at the cutting interface. This approach reduces heat generation at the source while providing sufficient lubrication for materials such as aluminum or other non-ferrous metals. MQL has become popular in industries prioritizing sustainability, as it dramatically reduces fluid consumption while still supporting highly accurate machining outcomes. Cryogenic cooling is another innovation, using liquid nitrogen or carbon dioxide to deliver ultra-cold temperatures that instantly remove heat from the cutting area. This method allows manufacturers to machine exotic alloys that typically generate significant heat, making it possible to maintain tight tolerances in materials previously considered too difficult or unstable for precision machining. Advances in sensor-based coolant monitoring systems further refine accuracy by regulating coolant pressure, flow rate, and temperature in real time. These smart systems help CNC machines automatically adjust coolant parameters based on the evolving cutting conditions, ensuring that precision is preserved even during aggressive machining operations. As CNC machines and tooling evolve, coolant systems evolve alongside them, offering new capabilities that expand what is technically possible in precision manufacturing.

The final and often overlooked impact of coolant systems on CNC machining precision lies in their contribution to machine stability and environmental consistency. Temperature fluctuations inside the machining enclosure, on the spindle, or around the machine frame can lead to micro-expansion of components, altering the relative positions of the tool, workpiece, and machine structure. Stable coolant circulation helps maintain a controlled environment within the CNC machine, contributing to thermal equilibrium that ensures accurate part-making even during long, demanding cycles. Additionally, coolant filtration and purification systems maintain fluid quality by removing contaminants such as metal fines, oils, and bacteria that degrade coolant performance. A clean, well-maintained coolant loop ensures consistent cooling and lubrication characteristics, preventing performance drift that could compromise precision. Manufacturers are increasingly adopting coolant chillers and advanced temperature control units that further stabilize machining environments. These systems maintain coolant at an optimal temperature regardless of ambient conditions or production load, enabling sub-micron accuracy in operations like mold making, medical machining, or high-precision aerospace component manufacturing. The role of coolant in environmental stability underscores its importance not only at the cutting interface but in the entire ecosystem of CNC precision.

In summary, coolant systems are far more than peripheral accessories in CNC machining; they are fundamental to achieving the precision demanded by modern manufacturing. From controlling temperature and stabilizing tool performance to removing chips and supporting advanced machining strategies, coolant systems influence nearly every variable that contributes to dimensional accuracy. As industries increasingly rely on complex materials, miniaturized components, and tighter tolerances, innovations in coolant technology will continue to shape what CNC machines can achieve. Whether through high-pressure delivery, cryogenic approaches, MQL systems, or sensor-driven automation, coolant systems are becoming integrated technologies rather than supplemental ones. Their impact extends from the microscopic details of tool-chip interactions to the macroscopic stability of the entire machining environment. As manufacturers push toward greater speed, sustainability, and accuracy, coolant systems will remain at the center of CNC machining advancements, ensuring that precision is not only achievable but consistently repeatable across every operation.